DRILLING RIG WITH SAW

BAUER SBA-VG45-D

SBA-VG45-D

Advantages & Features

Bores in long beams, profiles or flat bars are usually produced with magnetic drills, saw drills or moving column drills. The equipment available on the market is very expensive and only pays off with large series.

The quality of the work with magnetic drilling machines is person-dependent and very time-consuming.

This is why has developed a new generation of saw-drilling machines that is easy to operate and pays off even for small series. The data input does not require intensive training of the machine operator.

Advantages:

- Flexible production and short processing times

- High quality parts and less reworking

- Single parts, small and large series production

- Space-saving

- Easy and safe working

- Fast amortisation

- Robust and torsion-free steel construction,

solid German mechanical engineering - Also available in combination with horizontal saw

- On the roller conveyor, the feed tongs are mounted laterally on

a high-precision one, double linear guide. - The positioning accuracy of the material feed is between 0.1 and 0.2 mm.

- The standard feed length is 6 m (total length of the roller conveyor 9 m)

and can be extended up to 18 m according to customer requirements. - For parts longer than 6 m shuttle feeding takes place.

- The material is hydraulically clamped by the feed tongs.

- With a gripper the material can be completely clamped by the drilling system.

can be pushed. Since also on the right side of the band saw blade the material

can be clamped, the remnant piece length in the Automatic operation only

approx. 40mm (only with mitre band saw VG 450 L).

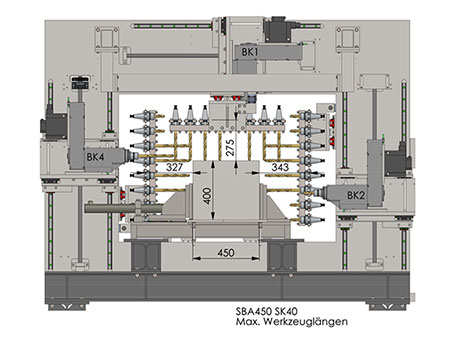

- The drilling rig is available with up to three drilling heads.

- Simple operation, no CNC knowledge required.

- Suitable for angle irons from 20 x 20 mm and flat irons from 20 x 5 mm, pipes, profiles etc.

- The drill heads are guided by high-precision, double linear guides.

- Positioning of the axes by servo motors and ball screws.

- X axis rack and pinion and servo motor.

- Distance between drill tip and saw band for version with the vertical

Saw only approx. 1700 mm. - The tool change is carried out manually or automatically by means of a

Laip quick-change system. - Each drill head is equipped with a separate spraying device.

- Infinitely variable speed adjustment between 140 and 2,000 rpm by

means of frequency converter. - Drilling capacity in standard steel of 25mm diameter possible.

- Tapping with floating tap holder.

- The drilling unit can be integrated into any saw (horizontal or vertical).

SBA-VG45D-D

Control & Programming

With the Bauer saw drilling rig the parts can be pushed through the drilling rig with an extension. This results in only a remaining piece of e.g. 20 mm. Depending on the material dimensions, there are different types of material clamping. Shown is a clamping with compressed air gripper for wall thicknesses up to approx. 5 mm.

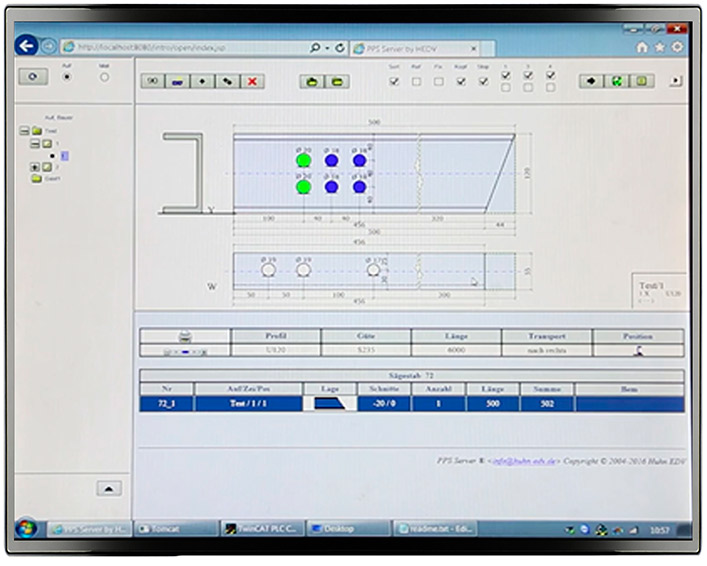

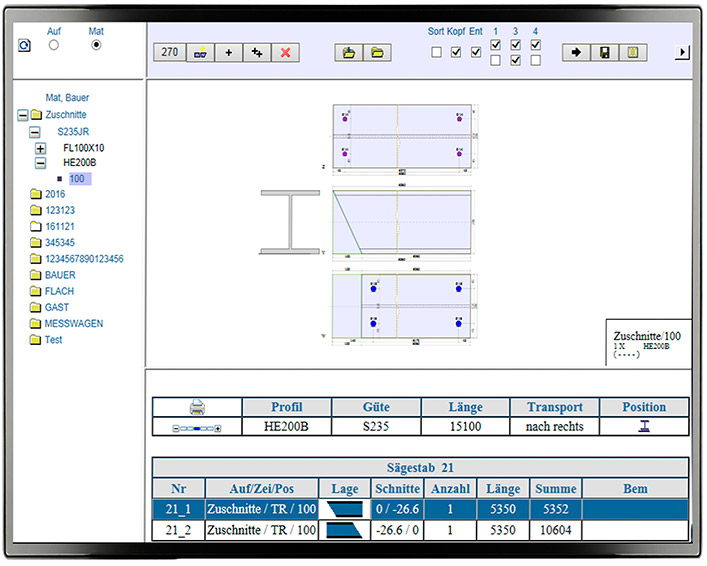

The parts can be easily created on the screen or imported by data import DSTV. The operator has information on the screen in which position the part is to be inserted.

Technical Data

Bauer Drilling Rig BA

| Drill heads | ||

|---|---|---|

| Material throughput through the drilling device with 200 mm long tools approx: | mm | 400 x 400 |

| Traverse paths of the drill heads | ||

|---|---|---|

| Drill head vertically under the table: Travel, horizontal approx. | mm | 600 |

| Drill head vertically under the table: Travel, vertical approx. | mm | 160 |

| Drill head vertically above the table: Travel, horizontal approx. | mm | 600 |

| Drill head vertically above the table: Travel, vertical approx. | mm | 600 |

| Drill head horizontal, right and left side: Travel, horizontal approx. | mm | 320 |

| Drill head horizontal, right and left side: Travel, vertical approx. | mm | 450 |

| Positioning accuracy of the drill heads | mm | 0,1 |

| Driving motor of the drill heads | ||

|---|---|---|

| Driving power of drill heads, standard | kW | 2,2 |

| Drilling capacity in standard steel at 2.2kW drive power | mm | ca. 25 |

| Driving power of the drill heads, option | kW | 4 |

| Drilling capacity in standard steel at 4kW drive power, option | mm | ca. 34 |

| Infinitely variable speed adjustment with frequency converter | 1/min | 140 to 2.000 |

| Material feed | ||

|---|---|---|

| Length of feed unit, standard | mm | 9.000 |

| Maximum feed length due to single stroke, without feed pliers | mm | up to 8.500 |

| Maximum feed length by single stroke, with feed tongs | mm | up to 6.000 |

| Feed pliers clearance height | mm | 320 |

| Positioning accuracy of the feed | mm | +/- 0,2 |

| Feed rate | m/min | 0 to 20 |

| Machine dimensions | ||

|---|---|---|

| Material support height (with VG 450 L as saw) | mm | 930 |

| Total length approx. | mm | 12.000 |

| Total width approx. | mm | 2.450 |

| Total height approx. | mm | 2.500 |

| Weight of the machine approx. | kg | 5.000 |

| Paint | ||

|---|---|---|

| Machine grey RAL | RAL | 7012 |

| Covers white RAL 7035 | RAL | 9002 |

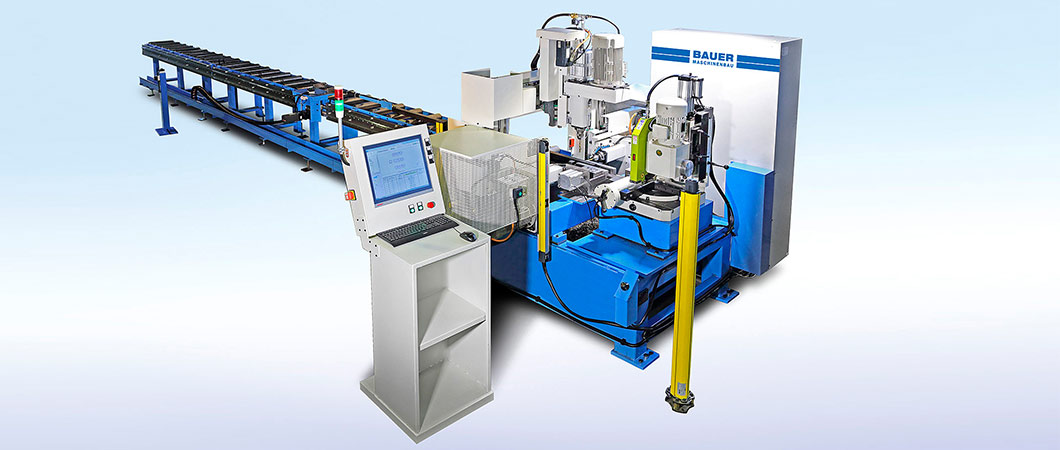

DRILLING RIG WITH SAW

BAUER BA 100 -3 KR

BA 100 -3 KR

Advantages & Features

Especially for small diameters we offer a 3-spindle drilling machine with a small circular saw or band saw.

According to special customer requirements we can also offer special solutions in the price regions of the standard machines. In the case of the machine shown, the entire system for the 80 mm x 80 mm profiles was kept very compact. Drilling spindle SK 40. A circular saw was used as sawing system.

Technical Data:

- All feeds with servo motors

- Drill spindle stepless 4/ 5.5kW, internal cooling

- Speed 3000 rpm, higher speeds are possible

- Dimensions profile dimension 100 x 100 mm

DSTV data import